Wellbore

Clean Out

ABOUT WELLBORE CLEAN OUT

The QMAX Mechanical Wellbore Clean up Systems have three objectives to ensure a cleaner Wellbore, to confirm the cleanliness of the wellbore and fluids and to save CLIENTS valuable rig time and cost.

The innovative design of the QTOOLS will clean the Wellbore more effectively and in most cases, in only one trip. Performing the entire Wellbore clean up in ONE SINGLE TRIP is the key focus for QMAX to ensure the client receives not only a high standard of service but also value for money.

When using a selection of QTOOLS a field support engineer can be on location throughout the operation, this is of course optional and at the discretion of CLIENTS.

All QTOOLS Engineers have extensive oil field experience with a continued internal training program set out for everyone.

Q SCRAPER

The Q SCRAPER is a rotating casing Scraper that is designed to scrape the casing walls to remove mud, cement and any other debris adhering to the casing or liner and place the debris into the fluid flow stream so that it can be effectively removed from the well. The Q SCRAPER is designed specifically for wellbore clean-up operations and has several features that gives superior performance over conventional “drilling” casing scrapers.

QBRUSH

The QBRUSH is a rotating casing Brush designed to brush the casing walls efficiently and effectively in order to remove mud and any other debris adhering to the casing / liner walls, especially fine materials and place the debris into the flow stream so that it can be removed from the well. The QBRUSH is designed specifically for wellbore clean-up operations and has several outstanding features that give excellent performance.

QMAG

The QMAG magnets are strong, large surface area magnets used to remove ferrous debris from the wellbore. This innovative magnet design creates a magnetic field and as a result, collects up to 4 times more material in a single run than conventional magnets. The tool can be run as a component to compliment most drilling / milling / polishing assemblies or as an integral part of the drill string during wellbore cleanup operations. It can be rotated and reciprocated without fear of damage to the casing or tools.

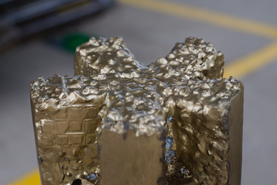

QMILLS

QMax have available a wide set of mills highly resistant to impact and with enhanced rates of penetration because of their design for different workover operations and well cleaner. We have available for casing sizes from 4 1/2" " to 13 5/8":

-

Junk Mills

-

Taper Mills

-

Taper Junk Mills

-

String/Watermelon Mills

OTHER EQUIPMENT AVAILABLE

- QTest tool.

- QFilter

- QJet BOP Tool

- By Pass Subs

- Drill Pipe

- Heavy Weight Drill Pipe

- Drill collars

- Mud motors

- Jars

- Crossovers